| Author |

Message |

Two Glove Boxes

Samba Member

Joined: March 03, 2005

Posts: 838

Location: Texas

|

|

| Back to top |

|

|

campingbox

Samba Member

Joined: November 14, 2000

Posts: 10196

Location: Petaluma, CA

|

Posted: Thu Jan 21, 2021 10:33 pm Post subject: Re: Melville Engineering steel and pipe 54' rhd single Posted: Thu Jan 21, 2021 10:33 pm Post subject: Re: Melville Engineering steel and pipe 54' rhd single |

|

|

| gatorwyatt wrote: |

Also, pedal bushings for RHD barndoors are somewhat basic but have honestly plagued me since I removed the pedals from the truck. Iím not a machinist and donít own any lathes and humans are well, humans and Iíve had a slow go at getting proper details out them. I think I may have an Avenue to try. Problem is the pin or shaft they ride on is slightly worn and itís got woodruff keys cut in it so machining it down and making a large ID bushing isnít possible because two of the parts that slide on the shaft are just pinched using the keys to hold stationary. Anyway more to come on that. |

Can you post photos of the complete assembly and the wear on the shaft? |

|

| Back to top |

|

|

gatorwyatt

Samba Member

Joined: April 24, 2002

Posts: 1867

Location: Clearwater Fl.

|

Posted: Sat Jan 23, 2021 10:06 am Post subject: Re: Melville Engineering steel and pipe 54' rhd single Posted: Sat Jan 23, 2021 10:06 am Post subject: Re: Melville Engineering steel and pipe 54' rhd single |

|

|

This is not everything... the throttle linkage is a skinny rod that goes through the inside of the pin/shaft and is not currently a concern to get these installed..

These take 2 small bushings and one large... one of the small bushing presses into the aluminum block. The other small bushing taps into the body ID of the ďtubeĒ that is part of the body. That same ďtubeĒ allows the clutch pedal ride on the OD of it via the large bushing.

As you can see on the pin itís only worn on one half of the pin/shaft. Not a super basic pin because itís hollow to allow the accelerator linkage to ride through it and it has indexed woodruff keys cut for pedals plus an indexed pass through for pinching the one pedal and the one arm.

This is the style bushing it came with...

This is what I found from one vendor

Problem is the small bushing came in an ID of 22mm. The pin/shaft is 21.90. Itís to loose. Those are of no use.

In the first pic the bushings sitting with the assembly are made by oilite. The small diameter bushing came in a OD of 24mm which is basically 24.03-05 for interference fit. They slid right into the aluminum block. Not loose and sloppy but wonít work. I had planned of cutting the ID which is 20mm to a nice fit around maybe 21.96??? But if they slid into the block and into the tube on the bus loosely they are of no use. I prefer to not use loctite to glue them

In. Havenít even started the clutch pedal bushing plan. The oilite bushing I sourced for it may press into the pedal and just need an ID cut and grease groove.

Side note: oilite are impregnated bushing with lubrication already in them. But cutting them mostly closes off the porosity of the lube and makes them no more self lubricating bushings.

_________________

www.blastserv.com

wanted:

RHD Barndoor floor mat..reproduction is fine |

|

| Back to top |

|

|

mr. warehouse

Samba Member

Joined: February 27, 2001

Posts: 5001

Location: Nor Cal 707

|

Posted: Sat Jan 23, 2021 2:05 pm Post subject: Re: Melville Engineering steel and pipe 54' rhd single Posted: Sat Jan 23, 2021 2:05 pm Post subject: Re: Melville Engineering steel and pipe 54' rhd single |

|

|

| gatorwyatt wrote: |

This is not everything... the throttle linkage is a skinny rod that goes through the inside of the pin/shaft and is not currently a concern to get these installed..

These take 2 small bushings and one large... one of the small bushing presses into the aluminum block. The other small bushing taps into the body ID of the ďtubeĒ that is part of the body. That same ďtubeĒ allows the clutch pedal ride on the OD of it via the large bushing.

As you can see on the pin itís only worn on one half of the pin/shaft. Not a super basic pin because itís hollow to allow the accelerator linkage to ride through it and it has indexed woodruff keys cut for pedals plus an indexed pass through for pinching the one pedal and the one arm.

This is the style bushing it came with...

This is what I found from one vendor

Problem is the small bushing came in an ID of 22mm. The pin/shaft is 21.90. Itís to loose. Those are of no use.

In the first pic the bushings sitting with the assembly are made by oilite. The small diameter bushing came in a OD of 24mm which is basically 24.03-05 for interference fit. They slid right into the aluminum block. Not loose and sloppy but wonít work. I had planned of cutting the ID which is 20mm to a nice fit around maybe 21.96??? But if they slid into the block and into the tube on the bus loosely they are of no use. I prefer to not use loctite to glue them

In. Havenít even started the clutch pedal bushing plan. The oilite bushing I sourced for it may press into the pedal and just need an ID cut and grease groove.

Side note: oilite are impregnated bushing with lubrication already in them. But cutting them mostly closes off the porosity of the lube and makes them no more self lubricating bushings. |

Can't you weld the pin and turn it to size in a lathe? |

|

| Back to top |

|

|

djfordmanjack

Samba Member

Joined: June 15, 2009

Posts: 2171

Location: Graz, Austria, Europe

|

Posted: Sat Jan 23, 2021 4:31 pm Post subject: Re: Melville Engineering steel and pipe 54' rhd single Posted: Sat Jan 23, 2021 4:31 pm Post subject: Re: Melville Engineering steel and pipe 54' rhd single |

|

|

It appears that both of the og bushings had holes for a grease fitting. if that holds true, the protruding grease fitting might hold the bushings in place inside , even if not a tight press fit. ( on certain years of beetles the pedal shaft is held in the aluminium bracket with a rather long grease fitting blocking its side to side movement)

also 21.90 would be a very, very lose fit in a 22mm bore. pretty sure the pin has worn off that much, I assume a typical 22 g6 (loose fit) fit should be around 21,97 or .98 or so for the shaft originally.

If you don't have access to machine shop or all of this becoming a PITA, I think you should use loctite on the bushings ( and clean off any left overs from the holes with solvent) and use that shaft as is. 0.1mm play isn't that much in the end really. not like that the pedals would wiggle around like crazy. the old bushings really looked pretty worn.

Good luck !

_________________

Hotrods, Fords, Veedubs and Triumph Twins !

52 Barndoor DLX Coachbuild project

55 Wolfsburg panel project, og paint Taubenblau L31

62 Dickholmer, custom color Seeblau L360

63 1500 Notch, og paint Rubin Rot L456

67 1500 Kšfer, og paint Lotus weiŖ L282 w/red interior |

|

| Back to top |

|

|

TvšttbjŲrn

Samba Member

Joined: May 07, 2004

Posts: 1431

Location: SoCal

|

Posted: Sat Jan 23, 2021 10:39 pm Post subject: Re: Melville Engineering steel and pipe 54' rhd single Posted: Sat Jan 23, 2021 10:39 pm Post subject: Re: Melville Engineering steel and pipe 54' rhd single |

|

|

I would look into getting round brass bar stock or thick wall tubing with a smaller hole in the center and larger outside diameter and have new bushings made to the size you need. The small lubricating holes can be drilled later carefully by hand by sliding the bushing over a rod of wood to have some support during drilling and do the final reaming after the bushing is pressed in. Cost more , but you know it is done right.

It appears the bushing you have were rolled / made from a flat piece of metal based on looking at the split with the partial holes. |

|

| Back to top |

|

|

campingbox

Samba Member

Joined: November 14, 2000

Posts: 10196

Location: Petaluma, CA

|

Posted: Sun Jan 24, 2021 8:58 am Post subject: Re: Melville Engineering steel and pipe 54' rhd single Posted: Sun Jan 24, 2021 8:58 am Post subject: Re: Melville Engineering steel and pipe 54' rhd single |

|

|

Itís probably easiest just to make a new pin.

That pin could also be spray welded and turned down. |

|

| Back to top |

|

|

mr. warehouse

Samba Member

Joined: February 27, 2001

Posts: 5001

Location: Nor Cal 707

|

Posted: Sun Jan 24, 2021 11:44 am Post subject: Re: Melville Engineering steel and pipe 54' rhd single Posted: Sun Jan 24, 2021 11:44 am Post subject: Re: Melville Engineering steel and pipe 54' rhd single |

|

|

| campingbox wrote: |

That pin could also be spray welded and turned down. |

That's what I mentioned as well. Seems to be the easiest fix. |

|

| Back to top |

|

|

gatorwyatt

Samba Member

Joined: April 24, 2002

Posts: 1867

Location: Clearwater Fl.

|

Posted: Mon Jan 25, 2021 8:29 am Post subject: Re: Melville Engineering steel and pipe 54' rhd single Posted: Mon Jan 25, 2021 8:29 am Post subject: Re: Melville Engineering steel and pipe 54' rhd single |

|

|

I appreciate all your input fellas. Iím going to look into the thermal spray coating for the pin and a local friend is going to help make a set of bushings.

My plater suggested we build up nickel on the pin. Then have it machined back down. I suppose there are all kinds of methods Iím just scratching around trying to get input and take the path that seams most durable and one that doesnít require me begging for my parts back after they sat on a shelf for a month.

_________________

www.blastserv.com

wanted:

RHD Barndoor floor mat..reproduction is fine

Last edited by gatorwyatt on Mon Jan 25, 2021 8:36 am; edited 2 times in total |

|

| Back to top |

|

|

gatorwyatt

Samba Member

Joined: April 24, 2002

Posts: 1867

Location: Clearwater Fl.

|

Posted: Mon Jan 25, 2021 8:32 am Post subject: Re: Melville Engineering steel and pipe 54' rhd single Posted: Mon Jan 25, 2021 8:32 am Post subject: Re: Melville Engineering steel and pipe 54' rhd single |

|

|

| djfordmanjack wrote: |

It appears that both of the og bushings had holes for a grease fitting. if that holds true, the protruding grease fitting might hold the bushings in place inside , even if not a tight press fit. ( on certain years of beetles the pedal shaft is held in the aluminium bracket with a rather long grease fitting blocking its side to side movement)

also 21.90 would be a very, very lose fit in a 22mm bore. pretty sure the pin has worn off that much, I assume a typical 22 g6 (loose fit) fit should be around 21,97 or .98 or so for the shaft originally.

If you don't have access to machine shop or all of this becoming a PITA, I think you should use loctite on the bushings ( and clean off any left overs from the holes with solvent) and use that shaft as is. 0.1mm play isn't that much in the end really. not like that the pedals would wiggle around like crazy. the old bushings really looked pretty worn.

Good luck ! |

I looked at the grease fittings that came with the trucks pedal. They are relatively short but maybe sourcing a little longer one and a combo of the loctite it will be sufficient. The issue I had with gluing was service for the next person if and when these wear. I suppose if done right and greased that should be like never. Thanks as always!

_________________

www.blastserv.com

wanted:

RHD Barndoor floor mat..reproduction is fine |

|

| Back to top |

|

|

djfordmanjack

Samba Member

Joined: June 15, 2009

Posts: 2171

Location: Graz, Austria, Europe

|

Posted: Mon Jan 25, 2021 2:30 pm Post subject: Re: Melville Engineering steel and pipe 54' rhd single Posted: Mon Jan 25, 2021 2:30 pm Post subject: Re: Melville Engineering steel and pipe 54' rhd single |

|

|

there is a special Loctite for fitting hubs and bushings, I believe it is green ( the liquid). it can be removed by rather light force or reasonable heat. Best you ask your local machinery supply. I have no doubt it would keep your bushings in place.

_________________

Hotrods, Fords, Veedubs and Triumph Twins !

52 Barndoor DLX Coachbuild project

55 Wolfsburg panel project, og paint Taubenblau L31

62 Dickholmer, custom color Seeblau L360

63 1500 Notch, og paint Rubin Rot L456

67 1500 Kšfer, og paint Lotus weiŖ L282 w/red interior |

|

| Back to top |

|

|

mandraks

Samba Member

Joined: November 28, 2004

Posts: 7047

Location: Lawrenceville, Ga

|

Posted: Mon Jan 25, 2021 5:05 pm Post subject: Re: Melville Engineering steel and pipe 54' rhd single Posted: Mon Jan 25, 2021 5:05 pm Post subject: Re: Melville Engineering steel and pipe 54' rhd single |

|

|

| djfordmanjack wrote: |

| there is a special Loctite for fitting hubs and bushings, I believe it is green ( the liquid). it can be removed by rather light force or reasonable heat. Best you ask your local machinery supply. I have no doubt it would keep your bushings in place. |

looks to be correct medium strength thread locker

_________________

regards

Uli

----------------------------------------

'53 3-Fold Oval, L35 Metallic Blue, looking for a narrow hatch panel |

|

| Back to top |

|

|

melville

Samba Member

Joined: August 09, 2006

Posts: 1245

Location: Just Outside the Redwood Curtain

|

Posted: Mon Jan 25, 2021 9:43 pm Post subject: Re: Melville Engineering steel and pipe 54' rhd single Posted: Mon Jan 25, 2021 9:43 pm Post subject: Re: Melville Engineering steel and pipe 54' rhd single |

|

|

https://www.google.com/search?q=bearing+bore+locti...p;ie=UTF-8

I've used different levels of this stuff in bicycle, motorcycle, and VW applications. Eventually 20, 30, or 50 years of hack mechanics (including me) working on stuff need some of this to cover our tracks.

_________________

2000 M Roadster

79 R100RS

78 R100/7

75 R75/6

65 Standard Micro

57 Sedan |

|

| Back to top |

|

|

gatorwyatt

Samba Member

Joined: April 24, 2002

Posts: 1867

Location: Clearwater Fl.

|

Posted: Thu Feb 25, 2021 7:12 pm Post subject: Re: Melville Engineering steel and pipe 54' rhd single Posted: Thu Feb 25, 2021 7:12 pm Post subject: Re: Melville Engineering steel and pipe 54' rhd single |

|

|

Lot of amazing info has been shed on this subject... as earlier stated I researched and found the owners family of this single cab via the Albany historical society in Australia. Over the last few months they have all gathered some of the most mind blowing details and pictures.

I am sharing these and I think you all will feel the work this truck has performed and the part it played in this families lives is absolutely amazing. The owner, Jack Rijnvis was a pioneer in the early beginnings of Albany. Once you see and read this I think you will feel the same...

The Melville Engineering VW Utility. As remembered by Murray Rynvis January 2021

At the Rynvis Christmas get together, late December 2019, my brother Dale broke the news to us that someone in the USA is restoring Dadís VW ute. A contact had been made through our cousins in Albany, after a contact was made to the Albany Historical Society from the restorer in USA.

The funny thing about this, was just a few days before, I was wondering about Dadís old VW ute, if it had met the fate of many a vehicle of that era: had it been thrashed to its end, left to rust away in some farmerís paddock; only to be loaded up on a truck and taken to the local scrap yard or rubbish tip, crushed and sent to China for recycling/melted down, and its metal made into something else?

Gladly, we now know that it is not the case, and that someone in the USA, is restoring, ever so proficiently, Dadís VW ute.

I have 1950 and 1951 Buick Super convertibles (left hand drive) in my shed, ex USA, awaiting restoration. It isnít only us shifting cars from the other side of the world that take our fancy!

It has been great excitement to us that Todd has found us, and that we are able to offer him the story of the VW ute from when it was new, until it was sold, never to be seen by our family again.

My brother Lindsay has all of our parentís photographs stored at his house and has managed to find some very good pictures of the ute. I am sure that Todd is going to be absolutely ďblown awayĒ by what Dad did with the ute when he sees them.

I have decided to recollect memories of the VW here as I remember them, being a newborn until the age of 8 to 9 years old, during the time of Dadís ownership of the VW.

Before dealing with the VW, I think it appropriate to have a bit of an insight into our fatherís and motherís early lives, which will lead on to the history of the ute.

Jack Rijnvis was born in Holland 12th March, 1925 to a family involved in ship and barge repairs, having their own small shipyard in Hoogeveen. They were also involved in the local transport industry for some time as well. During WW2 and the German occupation of Holland at that time, Dad and his family kept a very low profile, hiding from the German soldiers and occasionally moved to other family memberís places during the cover of darkness to avoid detection, and the possibility of being found for forced labour. Life was very tough. Shortages of food, soap, fuel for heating, and other necessities taught everyone about resilience and self- preservation in such a tough situation. My father developed a very strong respect of the efficiency and discipline of the German army, and often spoke of it in his later years. He always said that the television show Hoganís Heroes was so far from the truth, and he refused to watch it.

After WW2 the family (Dadís father, himself and 2 brothers) resumed barge repairs and alterations, and local transport involvement.

After a few years Dad decided to leave the family business and emigrate to Australia, arriving at Fremantle Western Australia on December 23rd 1950, aged 25.

Not long after arriving, Jack gained a job as a welder/maintenance fitter at Wittenoom in the north west of WA. After several months he moved south to the northern goldfields for similar work at mining plants and townships. He later took short term jobs moving further south and eventually settling in Albany.

In July 1952 Dadís parents and 3 sisters emigrated from Holland, arriving in Albany with 30 tons of engineering machinery and a prefabricated house.

Early 1953 a partnership between Jack and his parents was formed as Melville Engineering Company. The name was a lot easier for customers to relate to, than the family name of Rijnvis. This business was very successful, doing the bulk of the structural steel work in the greater Albany area, and many maintenance contracts to local infrastructure.

1954: saw the building of the Campbell Road new premises, and MEC started also selling steel and pipe cut-to-order to a wide variety of customers.

The VW ute was purchased and was used to transport fabricated steel: some very long structures were carried, as pictured. As time went on the ute was modified to suit the many demands of the work being done at MEC. It would have been one of the larger utes being used at the time, as most utes were variants of cars.

I never got to ask Dad when and where the new VW was purchased and I was only about 8 or 9 years old when it was sold.

My grandparents were bought out of the partnership in 1962 by my parents. My Uncle, who was employed as Foreman, left MEC to start his own business in competition, and their business is today run by my cousins: the Koster family.

At MEC new machinery was purchased and a larger workforce employed to handle the large contracts of the time. About this time the signwriting and graphics were added after a bright yellow paint job.

In the next few years the VW became quite worn and tired, was painted over dark blue. It was sold in about 1965.

November 1967: my father sold Melville Engineering, staying on as Manager until November 1968. In 1971 our family moved to Busselton WA, starting a similar but smaller scale business. I purchased it from my parents in July 1988 and continue to operate it with my family today as SOUTH WEST STEEL PRODUCTS.

1974: our family (Dad, Mum and 6 children) had our surname spelling change to: RYNVIS by deed-poll (legal terminology). This made life a lot easier, as pronunciation didnít change. Just the spelling.

January 2010: Jack passed away aged nearly 84, after a happy retirement travelling to many places in Australia with my mother in their motorhome for nearly 20 years. He was a man of great vision and foresight. I often think that being from Europe gave him the benefit to foresee what was to come as our part of Australia developed. He made many astute business decisions because of this.

I greatly miss his offerings of suggestions when doing jobs even to this day, but often feel his presence as if he is tapping me on the shoulder saying: do it this way!

My Mother: Estelle, born 28th February 1929 at Ravensthorpe WA, being an only child to pioneer farming parents. After finishing primary school and correspondence education to year 8, Mum worked on the farm before deciding to move to Albany to find work and a different life in 1954.

Mum met Dad in early 1955 and they married in September 1956.

At the time, Mum worked at the Albany Town Council Office as a clerk/receptionist at the front counter. In those days the Registration of motor vehicles and trailers was done by the local council. Number plates were issued from the Council office for these registrations.

It was only a short while before the VW was purchased that Mum and Dad met. Dad used his parentís (oval window) Beetle for transport early on. I guess that a smitten Estelle issued the plates to Dad for the VW ute as: ďA . 789 ď and being a little less random than the other numbers in the 780 series. When the VW was purchased, Mum evidently said of the VW ute: ďit didnít bother me at all. It was clean and tidyĒ

The VW was used on their dates, and It was definitely the means of transport during their courtship and well beyond. The VW did several trips to Ravensthorpe to visit Mumís parents on occasional weekends. The road was bitumen for half the distance, and unsealed loose gravel for about 100 miles. The oil bath air cleaner would have worked overtime on those trips!

My mother now almost 92, has very faded memories of the VW, does remember that it was a very important vehicle to my father and the family in those days.

Albany (pronounced as in the name Alan: Al-ban-ee) was the site of first white settlement in 1826 of Western Australia. It was, and still is one of the larger cities outside of Perth, the capital. The population in 1953 would have been around 5000 people.

Albany has a very large natural harbour with port facilities and activity was starting to happen after things had settled down, post WW2.

By todayís standards, there was a shortage of equipment such as cranes, large trucks, semi-trailers, earthmoving equipment; and even tools, engineering equipment and machinery that we take for granted today. Not many people had arc welders. Materials such as steel was in short supply, with limited sizes and profiles being available. At Melville Engineering, these materials had to be ordered months in advance, and in large quantities. A lot of work was done by simple and manual methods (not quite as primitive as building the pyramids!).

In general, people werenít as affluent as they are today.

Consequently, structures built were lightweight and transport methods were much different to today. The VW was used to transport some long loads such as a fifty (50) foot long roof truss one time, as pictured, and delivered to site during the day amongst normal traffic!

Such moves like this were capitalised on as promotional opportunities for Melville Engineering, as there were signs made and placed in the back of the ute during these shifts. Those methods are not allowed these days as regulations have been tightened and transport methods have changed.

The 1100cc VW seems a grossly underpowered vehicle by todayís standards, but speed wasnít the issue: getting ďitĒ there was. It also was a vehicle that could be taken to sites of basically bare dirt and tracks alongside railway lines and pipelines. I cannot remember hearing that it got bogged anywhere, but Iím sure that there would have been a few times it needed a tow out of a problem area.

I have no idea from where the VW ute was purchased, and who the dealership was. I feel sure that it was purchased in Perth, 254 miles from Albany in 1955. The road back to Albany was partially sealed with some sections gravel. Jack Rijnvis was the first owner.

Before the VW, Dad had also travelled around on his DKW 125cc motorbike that had been sent out from Holland in 1951. (I have it restored now). He would have ridden it to Perth from Albany to pick up the ute, and returned with the DKW on the back, under a Ďpermití to drive the VW back to Albany.

The VW became his main means of transport, privately and for business. During my parentís engagement, my Mum borrowed the ute to visit Dad in hospital due to an industrial accident. Mum was apprehensive to start with, as it had been a while since she had driven a car. On the way home while doing a turn at an intersection, there was a collision with a MG car travelling at speed. The driverís side front wheel and door on the VW were struck, with my mother being flung out of the ute. She suffered mild concussion, being hospitalised for one day. The VW was able to be driven to Dadís parentís house afterwards by his father and the damage was repaired by a local panel beater and covered by insurance.

When first married, it was used on my parentís honeymoon, travelling over 1200 miles.

I was brought home in the VW from hospital after I was born in 1957. There is a picture of this. The VW was the only car that Dad and Mum had until a second car was bought for my mother to cater for a growing family in about 1960. Having a second car for the family was very unusual in those days, according to my mother, as most families had only the one car or ute, and used their work vehicle for personal use and Sunday outings! Also in those days a lot of tradesmen worked 5 1⁄2 or 6 days per week, including Dad. Early on we often went to Emu Point: a beach just out of Albany townsite for Sunday afternoon family outings in the VW, parking on the hard sand at the beach as everyone did, until my second sister Carol was born. The front seat could only take 2 adults and 2 small children across it! (or one sitting on Mumís lap). In those days, Mum had a sheet of strong fabric attached from above the windscreen stretched across to the back of the cab, a bit like a hammock, in the middle to left area. This was to store nappies, spare clothes and blankets for us children when going on these outings. A picnic basket with food and drinks would go on the floor on the left side of the gearstick.

Dad had a leather covered transistor radio about half the size of a lunch box that he carried and listened to on the elevated lawn area near the car at the beach. The VW didnít have a radio. I donít think that the VW had a heater either.

As time went on, the condition of the ute changed mainly due to the rigors of being used as a transport and site vehicle for a busy engineering business. Unfortunately, I donít remember the ute as being in

pristine condition. By the time that it starts as a memory for me as a young child, the VW had been heavily used for about 5 or 6 years.

Work vehicles tend to show how they are being used, and deterioration due to age also is evident. I remember it as having patches of red oxide paint on surface rust areas, and the paintwork being faded. The tray body sides werenít there, and they were at Melville Engineeringís workshop being used as edging on a mezzanine floor above the office area.

It didnít matter if a modification was done, as it was a work vehicle, and things were done to it to suit the demands of the work being done. Bar work was added to the back of the cab, used as supports to hold those trusses being carried alongside the vehicle. The floor behind the cab was taken out to create a well body. Side doors with a hinge up ramp inside on the left side of this well were added. The oxy set and other heavy items could be wheeled into the well. Toolboxes and crow bars etc didnít need securing because they were contained in this well area. When doing site work, the remaining tray section was used as a work bench.

The trafficators changed also. I struggle to remember if indicator lights were added, but I know that the solenoid activated side indicators were damaged beyond repair being covered over or taken off. Somewhere along the line I was given a set of those to play with, but Iím not sure if they came off the VW.

Dad had men working at Melville Engineering that werenít Ďweldersí. At one stage the was a man : Dave, Ďfrom the circusí working at MEC. Dad had quite a few contracts erecting drive-in picture screens in towns up to 150 miles out of Albany, and Dave was a the one to climb to the top to disconnect the tow ropes after the screens were pulled up by a bulldozer. He wasnít scared of heights!

One day the VW came home painted bright yellow. Another man at MEC was doing the painting jobs. He also did cutting-off orders for people. This man was a signwriter and he painted the VW and the 2 Ford Prefect utes yellow before doing the signwriting on them all. I think that he was the one that designed the graphics, and he basically had Ďa blank canvasí to do his craft. To my knowledge, the graphics on the utes were not on any of the company invoices or other paperwork. The artwork was on the vehicles only.

During the life of ute during Dadís ownership, the motor had to be repaired a couple of times. I remember the ute being parked up in the garage at home, with the motor taken out, and the boot lid left open for a few weeks, at least once. Parts had to be sourced, and the mechanical work was done at home at night once all of us kids were tucked into bed.

I am led to believe that a fair bit of this mechanical work was done by my father on the kitchen table, and it seemed to be done reasonably quickly once the parts arrived.

There are some pictures of a canvas covered canopy on the ute, but that would have been in the early days, as I donít remember it. I do remember some ďlong/slenderĒ canvas pieces that we used as children to make ďtentsĒ with in the back yard, and I think that they may have been from the VW canopy.

One of the important and unconventional additions o the VW were what were called the Ďoutriggersí. These were 2 inch pipes facing outwards, either welded or bracket bolted front and back, or right across under the floor pan, lower down: just below the bodyline. Four ends in total permanently there, but not protruding and hardly noticeable. Into these stubs the outriggers made of 1 1⁄2 pipe were slid in when required and each secured with a bolt. Once in place they protruded about 12 inches or so from the body and each had 3 vertical brackets welded to them about 6 inches high. Trusses, frames etc could be supported on these and attached to the bar work at the back of the cab. If the door couldnít be opened, Dad would climb through the window to get access inside. By carrying trusses this way, the low carrying point gave the load a low centre of gravity and they could be lifted onto the outriggers by hand by a couple of strong men, one end at a time. Also, by carrying them this way, lateral distortion of the truss was kept to a minimum. One Saturday afternoon, I remember going with Dad in the ute, delivering a couple of 6 inch I beams about 15 foot long loaded on one side, and some pipes on the other side placed on the outriggers. Modern regulations donít allow this method of transportation anymore. I donít recall anyone else using

this method. There are semi-trailers (some extendable) and lots of lifting equipment these days, for dealing with long loads.

In about 1965 the VW was painted again. This time in a dark blue colour, but different to the original colour. The ute had become quite tired, with the odd dent here and there. I canít remember about the rust situation of previous years, but there were no large rust holes that were apparent. Dad also said that the motor was in need of doing again soon.

A friend of Dadís in Rotary was just trading in his 1963 Rover at the local Ford dealership. This was purchased by Jack, and the VW ute was sold privately. The Rover became Dadís mode of transport to and from work, and he enjoyed the newfound luxury driving, compared to the ute. Later on, a Bedford 2 ton truck was bought by Melville Engineering. The type of work being done at Melville Engineering also changed from lightweight, labour intensive structures to steelwork using universal beams requiring less labour: a reflection of the times, as wages increased.

The restoration and recreational use of older cars, motor cycles and trucks in Australia has gained ever increasing popularity since the 1970ís. Today, VWs are popular in this regard. The split window Kombis are the most sought after here. I am glad that Dadís VW has been saved, but a little disappointed that it left Australia, and 20 years ago! Once Covid has been sorted out, I would like to one day see Dadís ute again, once restoration has been completed, now in the USA. I wish Todd every success and good luck as he continues with the restoration.

Since starting this text, I have received some further information from my sister Carol regarding our parentís early days with the VW ute.

I hope that you enjoy these reminiscences, as much as I have, it putting these memories to text.

_________________

www.blastserv.com

wanted:

RHD Barndoor floor mat..reproduction is fine |

|

| Back to top |

|

|

gatorwyatt

Samba Member

Joined: April 24, 2002

Posts: 1867

Location: Clearwater Fl.

|

Posted: Thu Feb 25, 2021 7:46 pm Post subject: Re: Melville Engineering steel and pipe 54' rhd single Posted: Thu Feb 25, 2021 7:46 pm Post subject: Re: Melville Engineering steel and pipe 54' rhd single |

|

|

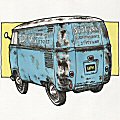

Looks like I found where the rim that was questioned on page 3 came from..

_________________

www.blastserv.com

wanted:

RHD Barndoor floor mat..reproduction is fine

Last edited by gatorwyatt on Thu Feb 25, 2021 8:25 pm; edited 1 time in total |

|

| Back to top |

|

|

gatorwyatt

Samba Member

Joined: April 24, 2002

Posts: 1867

Location: Clearwater Fl.

|

Posted: Thu Feb 25, 2021 8:08 pm Post subject: Re: Melville Engineering steel and pipe 54' rhd single Posted: Thu Feb 25, 2021 8:08 pm Post subject: Re: Melville Engineering steel and pipe 54' rhd single |

|

|

_________________

www.blastserv.com

wanted:

RHD Barndoor floor mat..reproduction is fine |

|

| Back to top |

|

|

gatorwyatt

Samba Member

Joined: April 24, 2002

Posts: 1867

Location: Clearwater Fl.

|

Posted: Thu Feb 25, 2021 8:21 pm Post subject: Re: Melville Engineering steel and pipe 54' rhd single Posted: Thu Feb 25, 2021 8:21 pm Post subject: Re: Melville Engineering steel and pipe 54' rhd single |

|

|

And my favorite of it out erecting a drive in movie screen

_________________

www.blastserv.com

wanted:

RHD Barndoor floor mat..reproduction is fine |

|

| Back to top |

|

|

campingbox

Samba Member

Joined: November 14, 2000

Posts: 10196

Location: Petaluma, CA

|

Posted: Thu Feb 25, 2021 10:43 pm Post subject: Re: Melville Engineering steel and pipe 54' rhd single Posted: Thu Feb 25, 2021 10:43 pm Post subject: Re: Melville Engineering steel and pipe 54' rhd single |

|

|

| Incredible. |

|

| Back to top |

|

|

Lind

Samba Member

Joined: November 06, 2000

Posts: 9913

Location: idaho

|

Posted: Fri Feb 26, 2021 7:44 am Post subject: Re: Melville Engineering steel and pipe 54' rhd single Posted: Fri Feb 26, 2021 7:44 am Post subject: Re: Melville Engineering steel and pipe 54' rhd single |

|

|

Wow, totally awesome. Are you going to restore it to yellow with logos?

_________________

.

Wanted:

Idaho VW license plate frames or other dealership items.

VWoA literature and early dealership or distributor literature/pictures/information

. |

|

| Back to top |

|

|

sled

Samba Member

Joined: February 16, 2005

Posts: 6179

|

Posted: Fri Feb 26, 2021 8:11 am Post subject: Re: Melville Engineering steel and pipe 54' rhd single Posted: Fri Feb 26, 2021 8:11 am Post subject: Re: Melville Engineering steel and pipe 54' rhd single |

|

|

Incredible! congrats on getting such wonderful contact

| Lind wrote: |

| Wow, totally awesome. Are you going to restore it to yellow with logos? |

now having seen these photos and story, that would be absolutely amazing.

_________________

drive your split. |

|

| Back to top |

|

|

|