| Author |

Message |

charleslabri

Samba Member

Joined: December 08, 2019

Posts: 649

Location: Nashville/Yosemite

|

Posted: Fri Dec 27, 2024 10:26 am Post subject: Re: 1981 (@wileythewesty) TDI conversion, from ground up Posted: Fri Dec 27, 2024 10:26 am Post subject: Re: 1981 (@wileythewesty) TDI conversion, from ground up |

|

|

| 4Gears4Tires wrote: |

| Needing to defrost the windshield is a good point about having AC. |

You know, its funny. My wife and i camped out in Chattanooga this last summer and hit a rainstorm on the way home. I pointed those vents at the windshield and felt good about installing the AC. From an AC pov, not that worth it (for me), but from a defrost pov

_________________

-------------------------------------------------

An example of my labor in action:

https://www.instagram.com/wileythewesty/

My Build Thread:

https://www.thesamba.com/vw/forum/viewtopic.php?t=730525&highlight= |

|

| Back to top |

|

|

4Gears4Tires

Samba Member

Joined: October 08, 2018

Posts: 4370

Location: MD

|

Posted: Thu Dec 26, 2024 7:39 am Post subject: Re: 1981 (@wileythewesty) TDI conversion, from ground up Posted: Thu Dec 26, 2024 7:39 am Post subject: Re: 1981 (@wileythewesty) TDI conversion, from ground up |

|

|

Needing to defrost the windshield is a good point about having AC.

_________________

'87 Syncro Ferric Oxyhydroxide Superleggera Edition

'85 Westy Sciuridae Domus Edition |

|

| Back to top |

|

|

charleslabri

Samba Member

Joined: December 08, 2019

Posts: 649

Location: Nashville/Yosemite

|

|

| Back to top |

|

|

charleslabri

Samba Member

Joined: December 08, 2019

Posts: 649

Location: Nashville/Yosemite

|

Posted: Sat Nov 09, 2024 9:06 pm Post subject: Re: 1981 (@wileythewesty) TDI conversion, from ground up Posted: Sat Nov 09, 2024 9:06 pm Post subject: Re: 1981 (@wileythewesty) TDI conversion, from ground up |

|

|

ALIKA T3:

no issue.. seemed to work. The ATE ones are compression and the Girling ones are cotter pins.

I guess goes for the universe here that ... they both fit. At least the ATE pins didn't fall out of the Girling calipers in my time using them

_________________

-------------------------------------------------

An example of my labor in action:

https://www.instagram.com/wileythewesty/

My Build Thread:

https://www.thesamba.com/vw/forum/viewtopic.php?t=730525&highlight= |

|

| Back to top |

|

|

ALIKA T3

Samba Member

Joined: July 30, 2009

Posts: 7284

Location: Honolulu,Hawaii and France

|

Posted: Fri Nov 08, 2024 6:10 pm Post subject: Re: 1981 (@wileythewesty) TDI conversion, from ground up Posted: Fri Nov 08, 2024 6:10 pm Post subject: Re: 1981 (@wileythewesty) TDI conversion, from ground up |

|

|

| charleslabri wrote: |

changed by pads today.

Girling calipers.. but they had ATE pins. So I replaced the ATE pins with Girling pins and then put ATE dust covers

the amount of information on Girling early vanagon pad changes on the internet.. zero

used some cool grease for the pins

|

What was the issue, they're very similar designs? One needs cotter pins to secure the pins, the other (ATE/Teves?) are just punched in, some kind of friction ring secures them.

_________________

Silicone Steering Boots and 930 Cv boots for sale in the classifieds.

Syncro transmission upgrade parts in the Classifieds.

Subaru EJ22+UN1 5 speed transmission

http://www.thesamba.com/vw/forum/viewtopic.php?t=416343

Syncro http://www.thesamba.com/vw/forum/viewtopic.php?t=4...num+gadget |

|

| Back to top |

|

|

charleslabri

Samba Member

Joined: December 08, 2019

Posts: 649

Location: Nashville/Yosemite

|

Posted: Fri Nov 08, 2024 4:26 pm Post subject: Re: 1981 (@wileythewesty) TDI conversion, from ground up Posted: Fri Nov 08, 2024 4:26 pm Post subject: Re: 1981 (@wileythewesty) TDI conversion, from ground up |

|

|

changed by pads today.

Girling calipers.. but they had ATE pins. So I replaced the ATE pins with Girling pins and then put ATE dust covers

the amount of information on Girling early vanagon pad changes on the internet.. zero

used some cool grease for the pins

_________________

-------------------------------------------------

An example of my labor in action:

https://www.instagram.com/wileythewesty/

My Build Thread:

https://www.thesamba.com/vw/forum/viewtopic.php?t=730525&highlight= |

|

| Back to top |

|

|

charleslabri

Samba Member

Joined: December 08, 2019

Posts: 649

Location: Nashville/Yosemite

|

|

| Back to top |

|

|

MarkWard

Samba Member

Joined: February 09, 2005

Posts: 18964

Location: Retired South Florida

|

Posted: Mon Sep 02, 2024 4:30 pm Post subject: Re: 1981 (@wileythewesty) TDI conversion, from ground up Posted: Mon Sep 02, 2024 4:30 pm Post subject: Re: 1981 (@wileythewesty) TDI conversion, from ground up |

|

|

| Any reason the Nomadic couldn’t be mounted lengthwise in the luggage rack? |

|

| Back to top |

|

|

charleslabri

Samba Member

Joined: December 08, 2019

Posts: 649

Location: Nashville/Yosemite

|

|

| Back to top |

|

|

charleslabri

Samba Member

Joined: December 08, 2019

Posts: 649

Location: Nashville/Yosemite

|

Posted: Wed Aug 28, 2024 6:05 pm Post subject: Re: 1981 (@wileythewesty) TDI conversion, from ground up Posted: Wed Aug 28, 2024 6:05 pm Post subject: Re: 1981 (@wileythewesty) TDI conversion, from ground up |

|

|

Hey Oli!

So the trans thing. It sort of ended with a whimper. I could never get ahold of the dude who did the work here in nashville- rustybottom garage. I should probably make an effort again.

I was sort of sidetracked because the shop here in nashville that dropped the trans for me (i just felt like paying someone else to deal with it) ended up not torquing the CVs back on and wrecked one of them. Sort of pissed me off and i just replaced it last week.

Regarding the AC, ive got a 550w solar panel on top the van and 200ah of batteries. With the sun beating down on that panel i can sustain a fair amount of AC, but honestly it sucks juice. I have a dc/dc that i need to install to see if it can soften the blow better than the solar. Solar is great, but performance can be inconsistent with clouds, dirt, etc.

Its on my list to pop in when i get a little reprise from the heat.

Funny enough, just this week i had the AC cranking and my wife was just dying of heat in the van and took all the AC on her. I realized that i had the vanistan intake thing open, causing 100f air to pull in from outside, then i had the control for the cabin radiator set to allow that 100f air to pull across that rad and kick out the lower vents. Superheated air was pulling into the cabin more than the AC could cool. I closed it all up and the AC does much better now

If i were to do this over again id recommend AGAINST the Nomadic unit. I had some spare cash laying around and was like, sure why not. Under the hood its the same as any other unit for cheaper on the market. The unit is lower profile, but longer in depth which causes issues for the specific spot it sits in the vans. The dometic or other chinese brands are not as deep and look better in the final install. Id bet dollars that the Nomadic units are just marketing. If anyone has a dometic unit and wants to side by side the output, would love to test my theory. Part of me thinks a careful placement in the pop top would be better… or run a 12/24v mini split and just bring the lines inside rather than a big hole.

_________________

-------------------------------------------------

An example of my labor in action:

https://www.instagram.com/wileythewesty/

My Build Thread:

https://www.thesamba.com/vw/forum/viewtopic.php?t=730525&highlight= |

|

| Back to top |

|

|

OlisGarage

Samba Member

Joined: June 01, 2022

Posts: 249

Location: Indianapolis, IN

|

Posted: Tue Aug 27, 2024 8:00 pm Post subject: Re: 1981 (@wileythewesty) TDI conversion, from ground up Posted: Tue Aug 27, 2024 8:00 pm Post subject: Re: 1981 (@wileythewesty) TDI conversion, from ground up |

|

|

Can’t believe I missed the first post of the overhead AC. Wow, nice work!!! I am so glad that we have another samba user documenting this installation. This could be the perfect solution for the non AC vans to get AC while driving and while parked. A win win really.

A few questions. How are you powering the AC? I assume you have a beefy battery charger that charges the lithium and then those power the AC?

Secondly. How did your transmission issue end? Any more info to share?

Van looks absolutely fantastic. Your project and diesel swap definitely motivated me quite a bit to do it right the first time (within my abilities; though sometimes over budget). Thanks for sharing.

_________________

1981 VW Vangagon TDI (in progress)

1984 VW Rabbit Convertible (daily)

2003 VW Jetta Wagon TDI (recovering from a hit and run) |

|

| Back to top |

|

|

charleslabri

Samba Member

Joined: December 08, 2019

Posts: 649

Location: Nashville/Yosemite

|

Posted: Tue Aug 27, 2024 1:29 pm Post subject: Re: 1981 (@wileythewesty) TDI conversion, from ground up Posted: Tue Aug 27, 2024 1:29 pm Post subject: Re: 1981 (@wileythewesty) TDI conversion, from ground up |

|

|

Hey!

Been a bit since I posted, I have been daily driving my van all over the SE USA. Some learnings as well.

1. Its hot!

Today its 100f outside in the shade, the new AC setup was able to bring the internal van temp down (in the sun) from 110 inside to 80 inside. That's pretty good. The unit was on max AC pulling around 45a and crankin. Id say the thing that really needs to get beefed up with this unit is the fan. It's pretty weak in all honesty. Hardly reaches the back on full speed. I know it's a big volume to cool, but im thinking of getting a small fan internally to just circulate the air. Ive got 3m ceramic window tinting on all the windows (except the front, which I'll likely change).

I have been pretty worried about the wiring from the AC unit to the battery system just catching fire from heat. I have seen the wire in my setup get to 140f, which is way too hot for my general comfort. The sleeve rating is fine, but it's hot. A second criticism of the AC unit is the they sent out an aluminum wire. Trash. I think this is the first aluminum wire I have in the van, and I'll eventually rip it out and throw it in the trash. Weak and not as conductive as copper. For a run this length, copper is the way to go to keep conductivity up and heat down. It's a thicc boi at 2AWG, but Id replace it with a 2AWG copper.

One of the things I did to keep things cool is buy a thermal switch and set it to fire on at 90f, and wrapped the probe to the AC wire. That way the fan will kick on when the ambient is high in the electrical area or the wire starts heating up. This will draw cool air in from the floor into the electrical area there. So far, this hot ass day, it kept the temp on that wire around 100. Nice.

I just used a 120mm DC computer fan and a thermal switch (https://www.amazon.com/gp/product/B07H2ZDDF1).

Here is a pic of the unit from the inside and the outside (drawing in with the grate)

2. I finished off the mounting of the internal part of the AC unit. I ended up creating my own internal bracket and securing it with some steel from home depot.

It's not exactly where I want it, but it works. I really need to start getting to the finer points of my interior trim. Everything is rough right now. I wired up some UTV lights in there as well for now. One in the center and one over each door. It's nice to have a little bit of light when getting in the car at night. I dont have them hooked up to the doors, I'll have to do that later

3. My electrical is coming along as well. Its all rough ins, but Ive got:

- water pump + electric valves from @veedubdayspa in Bend

- stereo, a marine Kenwood BT only amp/head unit + a slew of focal speakers

- a lighting circuit for internal lights

- the truck fridge

- a beefy USB-C charger to rip my MacBook to full charge quickly

4. Some interior stuff.

My wife complained about the lack of cupholders, so I splurged and got the big metal box. It's nice, I dont mind stepping over it and having a lockable space is nice. Only think I DONT like is that now I can never swivel my drivers seat unless I remove that seatbelt plastic cover. 10m install, easy sauce

I got some floor mats for the winter, ooh so pretty

Ive been slowly getting the interior sort of roughed together. Currently it's kinda bolted in. It won't go anywhere unless I really smashed it up on a dirt road in rock country. Otherwise, currently serves its purpose.

_________________

-------------------------------------------------

An example of my labor in action:

https://www.instagram.com/wileythewesty/

My Build Thread:

https://www.thesamba.com/vw/forum/viewtopic.php?t=730525&highlight= |

|

| Back to top |

|

|

charleslabri

Samba Member

Joined: December 08, 2019

Posts: 649

Location: Nashville/Yosemite

|

Posted: Sun Jul 07, 2024 2:24 pm Post subject: Re: 1981 (@wileythewesty) TDI conversion, from ground up Posted: Sun Jul 07, 2024 2:24 pm Post subject: Re: 1981 (@wileythewesty) TDI conversion, from ground up |

|

|

Ok, so here's the process- pretty straight forward.

Following the advice of previous dude in here I worked hard to maintain (and was successful) the seal on the pop top as it drops down on the luggage rack.

Knowing that this was my rear most limit, I set the unit there and cut forward. I hated this, quite honestly. The Domestic is quite a bit wider, and not as long/narrow as the Nomadic unit. This is a big hit to the nomadic, and, if doing this again, might sway me toward the Dometic.

Due to the length of the Nomadic unit, I had to cut the luggage rack in two critical areas:

1. I had to cut the rear of the Nomadic shroud down. I can post a picture of this, but the top of the Nomadic shroud has about 1-2 inches of dead space in the rear. I cut this out so I could fashion the unit further rearward UNDER the luggage rack.

2. I had to (frustratingly) cut the lower portion of the front of the luggage rack all the way to about the `westfalia` lettering. This can be seen in the pics pretty clearly. I haven't road tested this to see if I get wind whistle up there- if I do I'll pull the pop top and make a little fiberglass shroud up there to reduce whistles.

The whole thing is really straight forward. It just sits up there and you bolt it into some sort of custom frame that you'll need to make. I got a few 36"x .25" rails that I'll cut and make an internal mount (I'll post about this when that's done).

The nomadic mounting brackets inside the unit are really poorly made. It's some threaded metal inserts that go into the plastic. The manual says you shouldn't exceed 3.5-5lbs of torque on these, but even at that torque, they fall out- really poor design here.

Currently I temp hooked the thing up (see my rigged electrical nightmare in the previous posts) and set it on eco cooling.

It's 110 inside the van. it's 2pm in the afternoon. Its humid. It's summer in Tennessee.

- In eco mode it's pulling 52A. That's right on target for the expected power draw from the tech docs.

The exterior of the van is 112f

Its dropped my van from 110f to 85f inside after 3h. It's consumed in total of 85ah since I turned it on.

Id say this is working as expected.

AMA if interested

_________________

-------------------------------------------------

An example of my labor in action:

https://www.instagram.com/wileythewesty/

My Build Thread:

https://www.thesamba.com/vw/forum/viewtopic.php?t=730525&highlight= |

|

| Back to top |

|

|

charleslabri

Samba Member

Joined: December 08, 2019

Posts: 649

Location: Nashville/Yosemite

|

Posted: Sun Jul 07, 2024 2:04 pm Post subject: Re: 1981 (@wileythewesty) TDI conversion, from ground up Posted: Sun Jul 07, 2024 2:04 pm Post subject: Re: 1981 (@wileythewesty) TDI conversion, from ground up |

|

|

Onto a new adventure: Installing some aftermarket AC in the vein of some of the others that have installed the Dometix RTX 2000. Instead, ive opted for the Nomadic X2- here's a few reasons why, and why I wouldn't.

Pros

- smaller roof cutout (14x14)

- lighter weight (57 vs 70)

- more BTU (11k vs 7k)

- cool black finish

- good quality support (so far)

Cons

- their marketing is off-putting. They need to tone down the pseudo science, and stop flooding the market with paid ads. Its horrid.

- their unit is too big for the vanagon luggage rack (more on this later)

- pricey (3k vs 2.4k)

Here's some pics, then I'll walk through the process.

Finished product (so far)

Without the luggage rack

Just the cutout with the foam gasket

Cut in the roof

Prepping to cut the roof, added cardboard to catch the metal flake

Fitting the unit in the luggage rack

Final cuts in the luggage rack

From the inside (not fully bolted/attached yet)

----------------------------------------------------------------------------

Install details in post two following-

_________________

-------------------------------------------------

An example of my labor in action:

https://www.instagram.com/wileythewesty/

My Build Thread:

https://www.thesamba.com/vw/forum/viewtopic.php?t=730525&highlight= |

|

| Back to top |

|

|

Sir Sam

Samba Member

Joined: July 19, 2009

Posts: 1724

Location: Fort Collins Colorado!

|

Posted: Sun Jun 02, 2024 7:32 am Post subject: Re: 1981 (@wileythewesty) TDI conversion, from ground up Posted: Sun Jun 02, 2024 7:32 am Post subject: Re: 1981 (@wileythewesty) TDI conversion, from ground up |

|

|

| AndyBees wrote: |

as I learned later, the TDI ECU needs a minimum number of volts to function. The loss or reduced grounding affected that voltage.

So, I installed a permanent ground strap directly to the engine block from the Van body. |

I can confirm the same thing from other diesel applications with the same Bosch ECU. Battery voltage drops low enough that something in the ECU doesn’t fire correctly, a transistor driver or something. The engine will still be cranking, but the ECU isn’t doing fuel control or firing injectors. The CANBUS and other functions are not effected by the low voltage, so it still looks alive, but just won’t run an engine at those low volts.

_________________

'91 Carat Westy

87' Syncro + '87 Westy conversion coming soon |

|

| Back to top |

|

|

charleslabri

Samba Member

Joined: December 08, 2019

Posts: 649

Location: Nashville/Yosemite

|

Posted: Sun Jun 02, 2024 6:46 am Post subject: Re: 1981 (@wileythewesty) TDI conversion, from ground up Posted: Sun Jun 02, 2024 6:46 am Post subject: Re: 1981 (@wileythewesty) TDI conversion, from ground up |

|

|

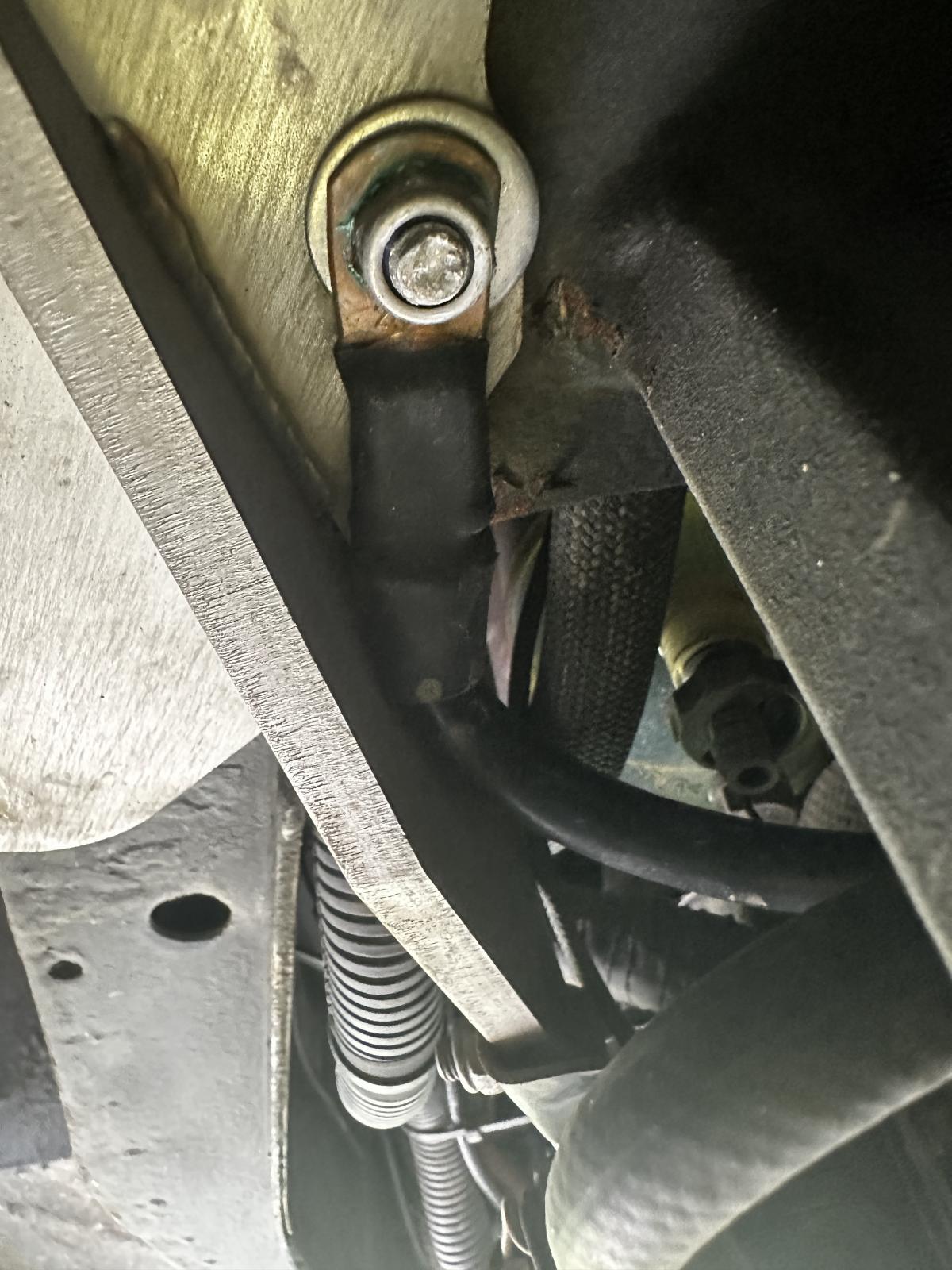

1. Ground strap

Ok, cool.. I have it mounted to the SS engine mount which is mounted to the frame. I'll just drill a new hole and put it there. I had originally mounted it on the engine frame mount since it was just very convenient and in the perfect spot. But I'll move it. Andy, I have known a few people who have a really hard time starting the boxeer kits that reach out to me from time to time. I'll pass this tidbit along to them. Ive never had issues starting my TDI, fires up perfect every time- probably due to me refreshing the OG ground strap and its connection points when I did the undercarriage.

2. OEM syncro cracks

I am not a diesel idler, but I will let the engine run for about 60-90s usually when starting it up cold before driving off. I wouldn't see this as excessive.

Regarding which syncos were used, I had Matt Steedle do the build back in 2020, unknown what syncros he used, but assuming top quality. He recently said that the syncros he used were NLA now. So I can assume it was the OG syncros.

3. Thrust damage on the 4th straight cut gear.

You can see the marring in the picture posted above. Not sure I can comment more on it since my words would only be pontificating and I wouldn't have any real answers. Id imagine Paul would be the best person to contact and see what he says.

4. decel on highway speeds in 4th.

Ok good to know that the issue shouldn't plague my straight cut gear. But lends me to just wonder what's going on here with the marring on the thrust surface.

5. Ground strap on front of trans.

As noted earlier, I'll move the new ground strap to a direct frame mount rather than piggybacking on the engine mount and then remove the front strap. I should have run a second battery cable when I did the rebuild. Being that I had never restored a vanagon, it just didn't cross my mind. I ran a really nice super beefy positive cable (to ensure maximum cranking amps) from the starter to the battery when I rebuilt the van (its visible in the picture of the ground strap in a braided industrial sheath.

_________________

-------------------------------------------------

An example of my labor in action:

https://www.instagram.com/wileythewesty/

My Build Thread:

https://www.thesamba.com/vw/forum/viewtopic.php?t=730525&highlight= |

|

| Back to top |

|

|

AndyBees

Samba Member

Joined: January 31, 2008

Posts: 2675

Location: Southeast Kentucky

|

Posted: Sat Jun 01, 2024 5:38 am Post subject: Re: 1981 (@wileythewesty) TDI conversion, from ground up Posted: Sat Jun 01, 2024 5:38 am Post subject: Re: 1981 (@wileythewesty) TDI conversion, from ground up |

|

|

I agree with Sodo about piggy backing anything on the main Ground Strap at the chassis as well as making sure it is grounded to fresh shinny metal.

Here's my experience with bad grounding at the OE site at the front of the transmission.

The TDI engine I installed was a "very hard starter" right off the bat. Hard starting plagued me for more than 18 months.......... new battery, several good used starters, a rebuilt starter, a new starter, re-sealed the injection pump, changed the fuel lines, changed the timing, etc., and about scratched the rest of my hair out. Oh, and I installed a Relay at the starter for the ignition start wire. None of these things changed anything with respect to starting the engine.

So, one day just to make sure the Starter was getting full power from the ground side, I installed a long ground cable from the battery out the sliding door under the Van directly to the starter .......... Dang, bam, bam, it started perfectly every time over and over. Wow, I said.

Bottom line, during the conversion project, I had installed the ground wire for the ECU directly to the ground strap on the chassis in piggy back fashion. The theory is that the starter was "sucking" heavily on the ground during the start mode. So, as I learned later, the TDI ECU needs a minimum number of volts to function. The loss or reduced grounding affected that voltage.

So, I installed a permanent ground strap directly to the engine block from the Van body.

_________________

'84 Vanagon Tin-top, ALH TDI, two trips to Alaska, 2014 & 16. 1989 Tin-top unmolested.

1983 Air-cool, 225k miles, 180k miles mine, seven trips to Alaska from 1986 thru 2003. 1975 Bay hopeful. |

|

| Back to top |

|

|

Sodo

Samba Member

Joined: July 06, 2007

Posts: 10739

Location: Western WA

|

Posted: Wed May 29, 2024 10:35 pm Post subject: Re: 1981 (@wileythewesty) TDI conversion, from ground up Posted: Wed May 29, 2024 10:35 pm Post subject: Re: 1981 (@wileythewesty) TDI conversion, from ground up |

|

|

| charleslabri wrote: |

Unfortunately, all of my OEM syncros were cracked. Sad day, but it finally shifts better. It took about 8k miles to destroy them all. I guess im pretty gentle.

Are you a "diesel idler"? Leaving your engine running in neutral for long periods?

I have heard of broken synchronizers recently.

SyncroShop thinks that it's possible that they are fatigued by idling unnecessarily (which is a "custom" of some diesel owners).

He has only heard of broken synchronizers on diesels with no DMF (Dual Mass Flywheel)

And they were "recent, NEW VW" synchronizers too (perhaps defective?).

We’ve heard of situation where the builder installed used, good condition OLD VW synchronizers and so far so good, but who knows?

You need a genuine expert looking directly at the parts as they come out of the gearbox.

I wish I could see the parts but I’m just “very interested”, (not experienced).

Man,,,,, I feel for ya on this one, I couldn’t know what to suggest.

But I’m interested.

Additionally, there was thrust wear on the straight cut gear from Paul. The local filed it down ever so slightly to add some clearance to the thrust surface of the 4th gear. I am not entirely sold on this, but we'll see what happens.

I wonder what caused the thrust damage.

It should never happen.

I wouldn't be “sold on it” either.

A very special machine called a "surface grinder" is necessary for such things.

Not many shops have them. I think Rancho has one.

The surfaces must be held parallel to tenths of ten-thousandths (inch),

an almost un-measurable parallelism, and impossible without a very specialized machine.

And after the metal removal - the “shaft end plays” etc must be flat/square/correct for many reasons.

a) ive read here that when sitting on the fwy, you should pull off throttle every once and a while to allow that 4th gear to get lubrication on the thrust surface. I do this now.

This “periodic decel” procedure is to mitigate the 4th gear lubrication deficiency for Vanagon helical-cut gears subjected to sustained thrust.

And its worse with high HP, the force is higher and the driver rarely lets up (or downshifts).

South African Oiling Plates is one band-aid that addresses this problem but we don’t know if it really helps. It can’t put the oil “inside” 4th gear where its needed.

The straight-cut gears specifically eliminate the thrust - you shouldn't need to "decel" periodically with straight-cut gears.

It is their specific purpose to eliminate this lubrication problem because the thrust of a straight cut gear is "zero"

b) ive also read that the front ground strap could cause corrosion on the gears through electronic futzing and give this look too. Hence why I added a starter to frame ground.

Good move. NOTHING good can come of electricity crossing bearings and gears and shafts.

Only detriment, arcing across bearings, making black dust that piles up on the drain magnet.

That black dust is burned steel that used to be part of your bearing races that has departed in a tiny fiery electrical explosion on the surface.

They are little but there is lots of them, especially during periods of “hard charging” such as replenishing a very hungry LiFePO4 Sunday eve on the drive home. And the 100A starting current is shorter but more intense.

If your transaxle cases are clean and shiny and bolts all shiny (like when your van left Stuttgart), the front strap doesn’t cause trouble. Its probably OK for 10,15, 20 years(?)

But if your steel bolts ever get a little corrosion on them, in their magnesium holes, then that front strap beckons electricity however it can get it. The current divides across any electrical paths it can find, some Amps crossing your bearings  . .

You want your (antique) gearbox to be a dead-end, that no electricity can cross any bearings, ever again.

I'll leave it up to time and the samba to figure out this one.

6. I added a better ground from the starter to the frame. I was hit/miss on this one but some folks here seem to swear by it and I have all the stuff lying around, so I did it in an afternoon. I still haven't removed the original ground strap at the front of the transaxle.

Delete that front strap. It's the devil (if your transaxle bolts corrode a little).

Realistically, if your new starter ground is really good, direct to the chassis, that leftover front ground strap can't hurt anything.....it's now unnecessary dead weight (delete it like a bad memory).

Your new ground strap should directly contact the welded vehicle chassis, not piggybacked onto a secondary item.

Every connection adds the possibility (the eventual inevitability) of resistance. Series resistance is additive. But minimizing the number of series connections between the starter and the battery is best. Some people will run a direct FAT negative cable from the starter to the battery, which isn’t real easy. I don’t think the voltage drops merit a direct FAT cable but there will be measurable drops at every connection.

Drill a hole for that copper lug, and clean it so that it's copper directly contacts "shiny chassis metal".

It should be the same as the negative strap on the battery- contacting directly to the welded chassis.

|

_________________

'90 Westy EJ25, NEW oil rings (!) 2Peloquins, 3knobs, SyncroShop pressure-oiled pinion-bearing & GT mainshaft, filtered, cooled gearbox.

'87 Tintop w 47k 53k, '12 SmallCar EJ25, cooled filtered original gearbox

....KTMs, GasGas, SPOT mtb |

|

| Back to top |

|

|

Sodo

Samba Member

Joined: July 06, 2007

Posts: 10739

Location: Western WA

|

Posted: Wed May 29, 2024 10:05 pm Post subject: Re: 1981 (@wileythewesty) TDI conversion, from ground up Posted: Wed May 29, 2024 10:05 pm Post subject: Re: 1981 (@wileythewesty) TDI conversion, from ground up |

|

|

| valvecovergasket wrote: |

| Zeitgeist 13 wrote: |

| ^^^especially on that silicone hose, which can be really slippery. I've seen those thinner screw clamps strip out numerous times. |

x2 i'll pile on here to say im not really a fan of silicone hose as its always more troublesome to get to seal - in my experience... |

I have found that mice like to chew silicone cookware.

It must be kind of satisfying.

Hopefully not hoses too.

_________________

'90 Westy EJ25, NEW oil rings (!) 2Peloquins, 3knobs, SyncroShop pressure-oiled pinion-bearing & GT mainshaft, filtered, cooled gearbox.

'87 Tintop w 47k 53k, '12 SmallCar EJ25, cooled filtered original gearbox

....KTMs, GasGas, SPOT mtb |

|

| Back to top |

|

|

Sodo

Samba Member

Joined: July 06, 2007

Posts: 10739

Location: Western WA

|

Posted: Wed May 29, 2024 10:02 pm Post subject: Re: 1981 (@wileythewesty) TDI conversion, from ground up Posted: Wed May 29, 2024 10:02 pm Post subject: Re: 1981 (@wileythewesty) TDI conversion, from ground up |

|

|

| charleslabri wrote: |

| Sodo had said somewhere that 180f is main bearing death. Other folks indicate that 210 is warning and 220 is death. |

220F is about the max temp that you should subject Dino oil to. If your gearbox temp exceeds 220F you should be using synthetic oil.

HOWEVER.....it's inopportune to "make use of" synthetic's high-temp capabilities 'cuz you are ruining your gearbox at those temps.

The main bearing can handle 180F.

The problem is 180F relaxes the thermal fit of the mainshaft bearing in its bore, allowing the bearing to move around and wallow out the bore, loosening it.

And the bearing can't transfer it's heat out to the gearbox case, and radiate it to the wind, when it's loose in its bore.

180F as a max has a little bit of 'safety factor' on a new gearbox because the bearing is 180F too and thus growing too. But if your gearbox is older, the bearing is looser. On really old gearboxes, the bearing is fully loose at room temperature.

As the mainshaft bearing bore gets worn loose (and loose due to heat), various bad things happen.

The two shafts spread apart, and the gears don't mesh correctly, rather than cool, quiet, rolling-tooth-contact, they start to "scrub" and run hotter (and wear more too).

A mainshaft bearing that can move in it's bore also messes with with the shaft end-play. The mainshaft bearing is a deep-ball bearing that is the official end-play-holder for the mainshaft.

If the bearing moves in its bore, because it's loose, the whole mainshaft moves that amount, along with it.

_________________

'90 Westy EJ25, NEW oil rings (!) 2Peloquins, 3knobs, SyncroShop pressure-oiled pinion-bearing & GT mainshaft, filtered, cooled gearbox.

'87 Tintop w 47k 53k, '12 SmallCar EJ25, cooled filtered original gearbox

....KTMs, GasGas, SPOT mtb

Last edited by Sodo on Wed May 29, 2024 10:44 pm; edited 4 times in total |

|

| Back to top |

|

|

|